Quinten Masijn, a doctoral student at KU Leuven, is researching how globular plant proteins can be applied in emulsified meat analogues, such as cooked sausage. His research focuses on drip loss and texture.

Half the Belgians who responded to a 2021 consumer survey said that meat substitutes do not have the texture and taste of the meat products they imitate. "In other words, meat analogues still have a different texture and taste, and need to be improved to satisfy consumer expectations," says doctoral student Quinten Masijn. His research is part of the work of the Meat Technology and Science of Protein-Rich Foods research group at KU Leuven.

Interactions

In particular, Quinten highlights the importance of the stabilizing interactions between plant protein on the one hand and oil and water on the other in these emulsified meat analogues. "You don't want any water or oil leaking out of the product during storage in a refrigerator, as that damages texture and flavour and looks anything but appetizing." The first question here is: which proteins, or which combinations of proteins, stabilize the meat analogue well and which work less well? The second question is: can we use a heating stage to increase or decrease stability, and how can this be explained?

Emulsified meat analogues

Emulsified meat analogues, such as cooked sausages, are characterized by a fatty gel structure. "The structure can be regarded as an emulsion of oil and water, stabilized by proteins," Quinten explains. "As part of the TETRA project 'MeatMimicMatrix,' we developed an emulsified meat analogue model system (protein, salt, water and fat) to conduct targeted research on the influence of plant proteins and fats as structure-forming components.

The first phase of my doctoral research focused specifically on the structure formation of proteins, that is, without the influence of fat or other structure-forming ingredients, such as starch," he continues. "Six commercial plant protein sources (chickpea, fava bean, mung bean, yellow pea, potato and soybean) were screened for their influence on the structure and stability of meat analogue model systems. We did this at three different protein concentrations: 17.5%, 20% and 22.5%.”

These systems were heated and cooled, and stability of the product (drip loss after centrifugation) was checked at various intervals. Long-term stability was also investigated by evaluating syneresis - drip loss - after three weeks' storage, as well as freeze-thaw stability. Third, the texture of the model system at the gel stage was assessed in terms of factors such as hardness.

Results

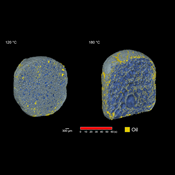

Thermal treatment resulted in improved structure and stability for all protein sources. Thus, before heating all the samples - except soy protein - lost a lot of moisture after centrifugation. This decreased significantly after heating, and decreased even more after heating and cooling. This is evidence first of the increased stability of these systems due to protein denaturation (during heating) and second of the presumed strengthening of hydrogen bonds and ionic bonds (during cooling). Potato protein showed the greatest increase in stability, and soy protein the least, but the latter was already very stable even when unheated. The effect of concentration on stability was heavily dependent on protein source, with a significant effect for chickpea, mung bean and pea, but not for fava bean, potato or soybean.

The effect of protein and protein concentration on the texture (hardness) of the formed gels was clearer. On the one hand, potato showed the greatest hardness, followed by soybean, followed by chickpea, fava bean, mung bean and pea. On the other hand, a higher concentration of protein led to increased hardness, i.e., harder gels, for all protein sources.

Drip loss

The stability of the gels decreased with prolonged storage at 5°C, leading to additional drip loss. Drip loss after one freeze-thaw cycle was in most cases similar to drip loss after long-term storage. Only for potato protein does drip loss seem to be significantly higher after one freeze-thaw cycle. During freezing, ice crystals can "puncture" the protein structures, increasing their drip loss, and thus reducing their stability. It therefore appears that the structures of potato protein are more susceptible to degradation by the formation of these ice crystals than other protein sources in combination with the freeze-thaw process. The effect of concentration is significant, but depends on the protein source, except in the case of chickpeas. Drip loss can be controlled in this way.

Conclusion

Heating greatly increases the stability of the model systems containing proteins, reducing drip loss, except for soy protein which is already very stable when unheated. The effect of protein concentration depends significantly on the protein source. The hardness of protein gels depends heavily on the protein source, but for all protein sources, a higher protein concentration leads to harder gels.

“It is always advisable to maintain a critical perspective on your own products and adjust them to contemporary needs where necessary”, emphasises Marijke Adriaens, CEO of frozen food company Fribona. “For consumers, taste is still the main consideration. It is essential to work towards a product that is, above all, tasty and visually appealing.”...

Scientists from KU Leuven have discovered how oil penetrates snacks during and after the frying process. Recent research findings point to advanced frying techniques that reduce oil absorption, as well as innovative methods to limit oil uptake during the cooling phase. This paves the way for the development of healthier snacks without compromising...

Food companies are increasingly targeting a wider range of consumer groups. Speaking at an event organised by Fenavian, Julian Mellentin of New Nutrition Business said this strategy offers significant opportunities to respond to the diverse health needs and interests of today’s consumers. “Consumers enjoy both animal and plant-based proteins”, he...

Backed by financial partners, Start it @KBC is launching the accelerator programme Scale it Agro, aimed at scale-ups offering sustainable and innovative agricultural solutions for agriculture and horticulture businesses. Kjell Clarysse, programme director at Scale it Agro, goes into more detail.