Artificial Intelligence and machine learning are taking giant strides. For his doctorate, Michiel Schreurs at KU Leuven researched how we can use AI to predict and understand the flavour of foodstuffs; where better to start than with Belgian beer. He starts off first of all with general conclusions on Artificial Intelligence and machine learning in practice.

“Modelling the flavour of products and processes is not new. Originally these models were based on statistical methods, which could be calculated without computers. Nowadays powerful computers make it possible to use AI and machine learning models to predict flavours or production processes. This approach is different and often more suitable for the processing of the available data, meaning that alternative models can make more accurate predictions. Thus the models may be better for handling data with many different variables or interactions between variables. Data could be process parameters, taste scores, consumer feedback, quality control accept/reject rates”, says Michiel Schreurs, VIB-KULeuven researcher.

Free software available

A second conclusion: “Surprisingly, computer programmers create modelling software to be as simple and user-friendly as possible to use. Software distributed for free makes it possible to develop these models without expensive licences. You do need a basic knowledge of programming, though. And last but not least: “Data quality is crucial. First the data must be of good quality. Secondly a model can only learn if enough good quality data is available. More data is also always better, but you can get started with fifty or so data points or even fewer. Models are not usually good at extrapolating, so they cannot make accurate predictions for situations for which they have not been trained, such as another type of food or process. So we need data on whatever it is that we want to model”.

250 different beers

The perception and value of the taste of beer depends on the interplay of many chemical connections and external factors, and thus appears challenging to understand and to predict. “To predict and improve complex beer tastes by machine learning, we combine extensive chemical and sensory analysis of 250 different beers to train machine learning models which make it possible to predict flavours and consumer evaluations.

More than 200 chemical characteristics

For each beer we measure more than 200 chemical characteristics, we carry out quantitative sensory analyses with a trained testing panel, we map out data from more than 180,000 consumer surveys in order to train ten different machine learning models. This called for three years of analytical and sensory research”, he notes. “Our study shows how big data and machine learning can expose complex links between food chemistry, flavour and consumer perception, and lays the basis for the development of new, custom-made foodstuffs with superior flavours.”

Predicting the flavour and value of foodstuffs on the basis of the chemical characteristics is, according to Schreurs, a largely intangible objective in sensory science, above all for complex foodstuffs and drinks. “A major obstacle is the immense number of flavour-determining chemicals which form the basis for the flavour of food. Flavour compounds can vary strongly in chemical structure and concentration, making them technically challenging and labour-intensive to quantify, even in the light of innovations. There are also differences between the flavour compounds that different people can taste, so they will experience the same foodstuffs differently.”

In his presentation at Intrafood:24 Michiel Schreurs shares insights, both in practical terms on how to use AI properly and why it is suitable for his research, and looking forwards to the wide range of potential applications of AI in the food sector.

www.verstrekenlab.sites.vib.be

“It is always advisable to maintain a critical perspective on your own products and adjust them to contemporary needs where necessary”, emphasises Marijke Adriaens, CEO of frozen food company Fribona. “For consumers, taste is still the main consideration. It is essential to work towards a product that is, above all, tasty and visually appealing.”...

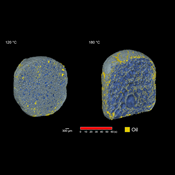

Scientists from KU Leuven have discovered how oil penetrates snacks during and after the frying process. Recent research findings point to advanced frying techniques that reduce oil absorption, as well as innovative methods to limit oil uptake during the cooling phase. This paves the way for the development of healthier snacks without compromising...

Food companies are increasingly targeting a wider range of consumer groups. Speaking at an event organised by Fenavian, Julian Mellentin of New Nutrition Business said this strategy offers significant opportunities to respond to the diverse health needs and interests of today’s consumers. “Consumers enjoy both animal and plant-based proteins”, he...

Backed by financial partners, Start it @KBC is launching the accelerator programme Scale it Agro, aimed at scale-ups offering sustainable and innovative agricultural solutions for agriculture and horticulture businesses. Kjell Clarysse, programme director at Scale it Agro, goes into more detail.